The following points should be paid attention to when the deceleration motor is in normal operation

The following points should be paid attention to in normal operation:

1) check the heating and oil leakage of the bearing frequently, and replace the lubricating oil regularly. The grease of rolling bearing should not exceed 70% of the volume of the bearing chamber.

2) the temperature of deceleration motor in normal operation shall not exceed the allowable limit. During operation, the operator on duty should always pay attention to and supervise the temperature rise of each part.

3) pay attention to keep the interior of the reduction motor clean, and do not allow water drops, oil stains and debris to fall into the interior of the motor. The air inlet of the reduction motor needs to be kept unobstructed.

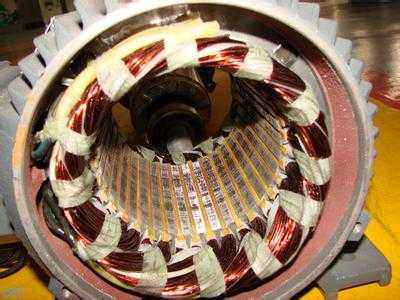

4) for wound rotor reducer motor, check the contact between brush and collector ring, brush wear and spark condition. If the spark is severe, it is necessary to timely clean the surface of collector ring and correct the tension spring pressure of brush.

5) supervise the power supply voltage, frequency change and voltage imbalance. If the power supply voltage and frequency are too high or too low, the three-phase voltage imbalance will cause current imbalance, which may cause overheating or other abnormal phenomena of the reduction motor. The current unbalance should not exceed 10%.

6) supervise the load current of reduction motor. When the deceleration motor is overloaded or fails, the stator current will increase sharply and the motor will overheat. All electrical equipment shall be equipped with ammeter to monitor the load current of the reducer motor. The load current of the deceleration motor in normal operation shall not exceed the rated current value specified on the rating plate.

7) pay attention to odour, vibration and noise of reduction motor. Because the temperature of winding is too high, it will give out the smell of insulation scorching. Some faults, especially mechanical faults, will soon be reflected as oscillation and noise. Therefore, when you smell burning smell or find abnormal oscillation or rubbing sound, or extremely loud buzz or other noise, you should immediately cut off the power to check.

Source: Jiangmen reducer http://m.plasticfield.com.cn

-

07-06

The difference between reducer and gearbox

Reducer motor mainly refers to the gear motor assembled by gear box and motor. Its main function is to increase the torque and reduce the speed. It is widely used in many factories. It is generally decelerated by means of gearbox. Reducer motor refers to the integration of reducer and motor (motor), which can also be called gear motor or gear motor. It is usually integrated and assembled by a professional reducer manufacturer and integrated with the motor. The reducer motor is a kind of power tr

-

07-06

What is the difference between asynchronous motor and synchronous motor?

The principle of asynchronous and synchronous motors are both based on the law of electromagnetic induction. The difference is that the symmetrical three-phase windings of the asynchronous motor are connected to the AC power supply. Even if the stator does not roll, a rotating magnetic field will occur because of the AC power supply. At this moment, the current will occur in the closed winding circuit. Therefore, according to the left-hand screw rule, the effect of the force on the current carry